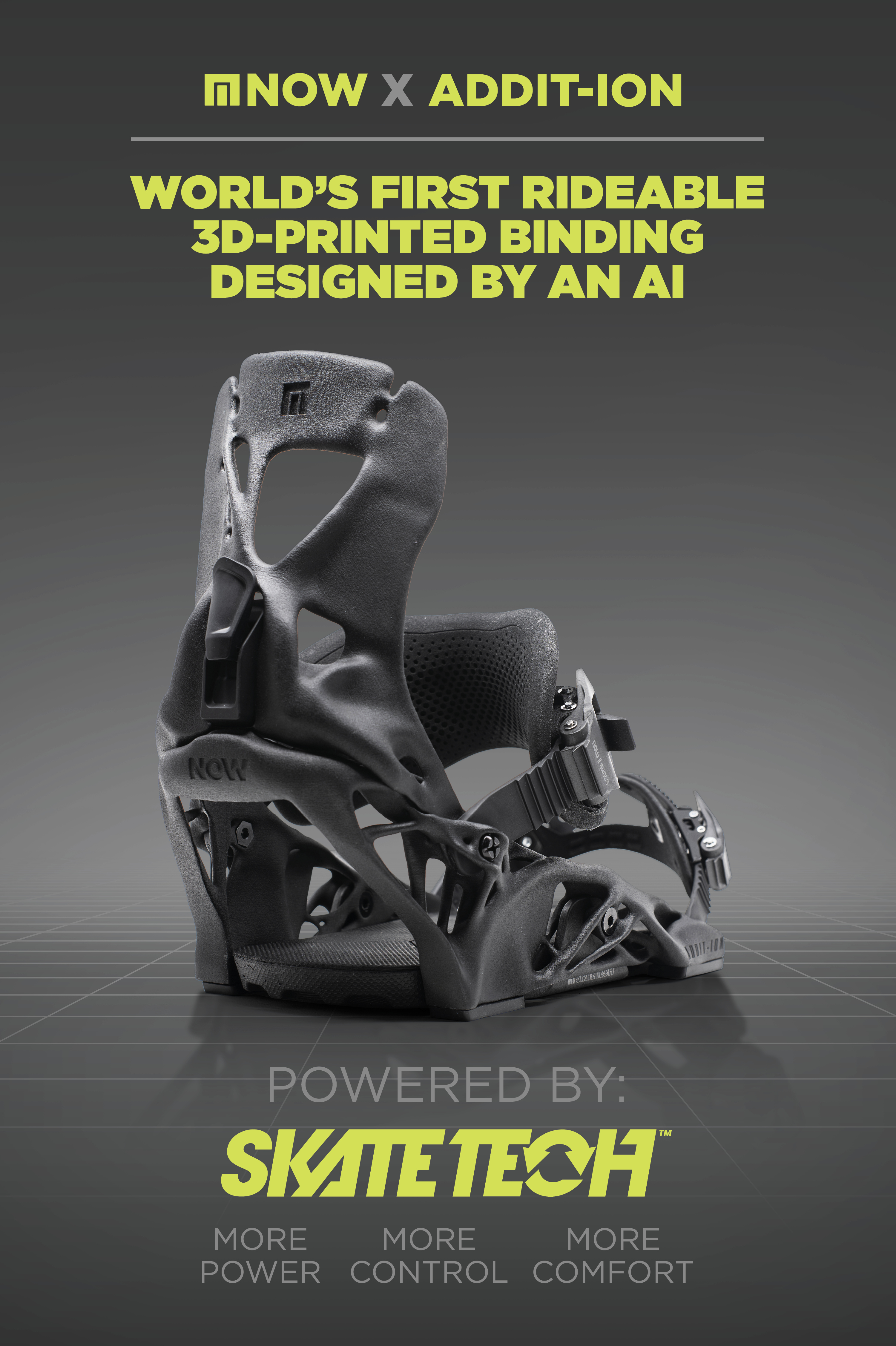

NOw x addit-ion

NOW R&D

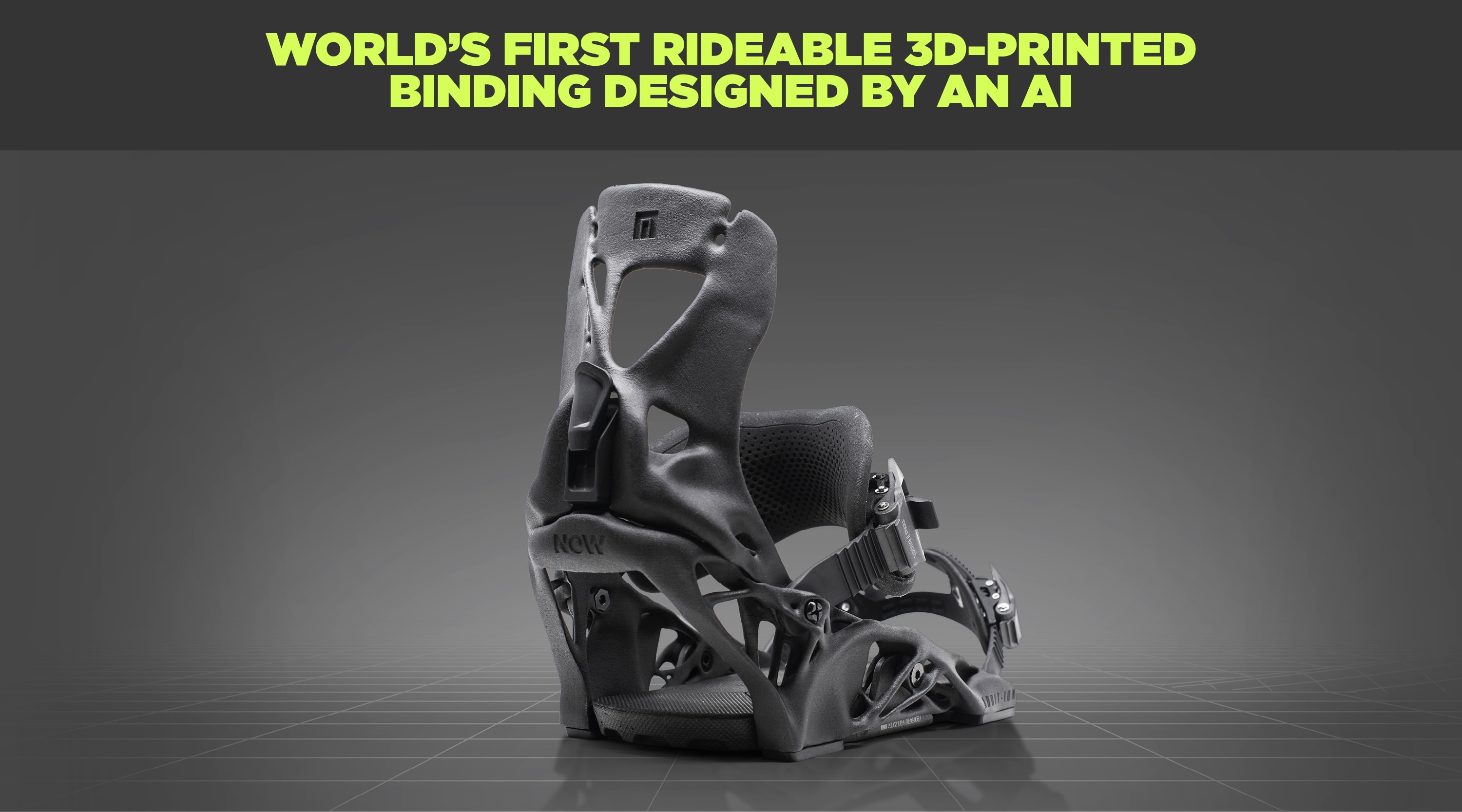

World's first rideable 3d-printed binding designed by an ai

The innovative snowboard brand NOW and ADDIT·ION, the Artificial Intelligence design specialists, have unveiled the first ever 3D-printed snowboard binding entirely designed by Artificial Intelligence.

To create a responsive binding, optimized for turning, the goal was to deliver maximum stiffness with the lowest possible mass. To make that happen, Addit-ion brought their mastery of AI design and 3D printing expertise, and NOW brought their patented Skate Tech Technology & extended knowledge in binding Technology.

Together we built a base plate that would emulate the stress that bindings undergo during aggressive carving. Then used a minimal mechanical representation of Skate Tech to generate the ultimate shape around it using the Autodesk generative design algorithm.

We had dozens of different outcomes to compare, with different materials and technologies, but after many hours of simulation and data analysis, we came up with the best option, and chose to print it using a material called PA 12. PA 12 is stable in cold temperatures, it bonds well together and has the mechanical property of regular PA 66 nylon which NOW use in the whole range of injected bindings.

“This concept binding is the starting point towards the new paradigm of sports gear, where optimization algorithms and mass customization will grant unique and tailor-made products for every specific need”, said Saulo Armas, co-founder of ADDIT·ION.

“The result is the A.I. BINDING, the first ever snowboard binding created by an Artificial Intelligence which - thanks to its design - is 25% lighter than current bindings.“ said Daniel Schmäh, R&D Director - Snowboard Bindings at NOW

Choosing 3D printing as the manufacturing method for the product wasn’t a trivial decision.

“This concept binding is the starting point towards the new paradigm of sports gear, where optimization algorithms and mass customization will grant unique and tailor-made products for every specific need”, said Saulo Armas, co-founder of ADDIT·ION.

“The result is the A.I. BINDING, the first ever snowboard binding created by an Artificial Intelligence which - thanks to its design - is 25% lighter than current bindings.“ said Daniel Schmäh, R&D Director - Snowboard Bindings at NOW

Choosing 3D printing as the manufacturing method for the product wasn’t a trivial decision.

The AI. bindings were printed on an HP Multi Jet Fusion 3D printer similar to the one above

“With powder-based printing technologies, you don't need any support material, and you can print almost any desired shape. This gave the algorithm absolute freedom to ascertain the best outcome without any manufacturing constraints.” said Oriol Massanes, artificial intelligence expert at ADDIT•ION.

3D printing also opened the door to redesign other parts of the binding, and most importantly opens the possibility of complete customization.

“To see the result of this knowledge exchange is simply incredible; 3D printing is the way of the future and we already used it for parts confirmation and other R&D projects. One of our machine runs 24/7 and with this newer technology we save time & money and we can get complex parts within 12hrs”. said JF Pelchat, founder of NOW bindings.

COMING SOON! We are in the final stage of testing and integrating this project within the NOW line up, our goal is to have a limited release ready for sale in 2021.

The Future Is NOW

The AI. bindings were printed on an HP Multi Jet Fusion 3D printer similar to the one above

“With powder-based printing technologies, you don't need any support material, and you can print almost any desired shape. This gave the algorithm absolute freedom to ascertain the best outcome without any manufacturing constraints.” said Oriol Massanes, artificial intelligence expert at ADDIT•ION.

3D printing also opened the door to redesign other parts of the binding, and most importantly opens the possibility of complete customization.

“To see the result of this knowledge exchange is simply incredible; 3D printing is the way of the future and we already used it for parts confirmation and other R&D projects. One of our machine runs 24/7 and with this newer technology we save time & money and we can get complex parts within 12hrs”. said JF Pelchat, founder of NOW bindings.

COMING SOON! We are in the final stage of testing and integrating this project within the NOW line up, our goal is to have a limited release ready for sale in 2021.

The Future Is NOW

addit-ion

ADDIT·ION is the first Design for Additive Manufacturing Studio capable of offering a complete, from concept to production, service.

After more than four years of specialization in design for additive manufacturing, Ignasi Sagré and Saulo Armas started ADDIT·ION, an end to end solution for additive manufacturing. With HP’s MJF technology as their main area of expertise in the Additive manufacturing they’ve carried out all sorts of DfAM projects, ranging from product design and topology optimization to parametric automated solutions, in sectors including automotive, aerospace consumer goods. Also, ADDIT·ION mentors companies that have decided or are willing to adopt Additive manufacturing technologies in their operations by providing them with education and consulting, helping them through the whole process.